The electric motor is the most critical component of your facility’s operations. When it is working correctly, it provides the highest level of efficiency, productivity, and safety for you, your clientele, and your workforce. Electric motors, just like any other moving component, can break down and cause extended downtime, potential dangers to people nearby, and lost profits. Very often, the motor will show some warning signs that mean an imminent breakdown, and they go ignored.

To avoid these situations, you need to make sure your facility has a proper working electric motor. Let’s go over the 5 reasons why your facility needs a new motor.

When Do You Need A New Electric Motor

Make sure you know how to identify the warning signs of electric motors. When you keep your eyes and ears open for them and get a jump on your electric motor problems and avoid any potential downtime in your facility.

#1 Catastrophic Failure

This kind of failure is the most extreme of the red flags that mean you need a new electric motor. You could have operations running as normal and then suddenly everything comes to a grinding stop. Whatever you need that motor for, you will see right away that something wrong is happening during that catastrophic failure moment.

Severe damage can often happen when a motor stops suddenly. This could be due to a rise in temperature, melted parts, or a mechanical issue that affects the shaft or frame. Repairs may be insufficient and you may need to get a new electric motor.

#2 Failed Inspection

You regularly have to hire a professional to inspect the electric motor. Motors are able to last for many years if you do preventative maintenance. Identifying potential problems can help extend the life of your motor which will keep it running for years.

However, an inspection can show some severe issues with the motor. It is always better to get the bad news that you failed the inspection and get a replacement than ruin your facility’s operation.

#3 Components That Overheat

Like we said before, an electric motor can fail catastrophically when components overheat. When a motor overheats is a result of an external source. If you see your motor is getting hotter than usual we recommend you investigate as soon as possible. If the motor is operating under these conditions for a long time, you should consider replacing it once that excessive load is resolved.

#4 Vibrations

Rotating equipment is designed to be able to operate within a specific range of vibrations. Once an apparatus operates outside that range, the electric motor is destined to fail. When excessive vibration is left unattended it can lead to catastrophic failure and render the motor unrepairable.

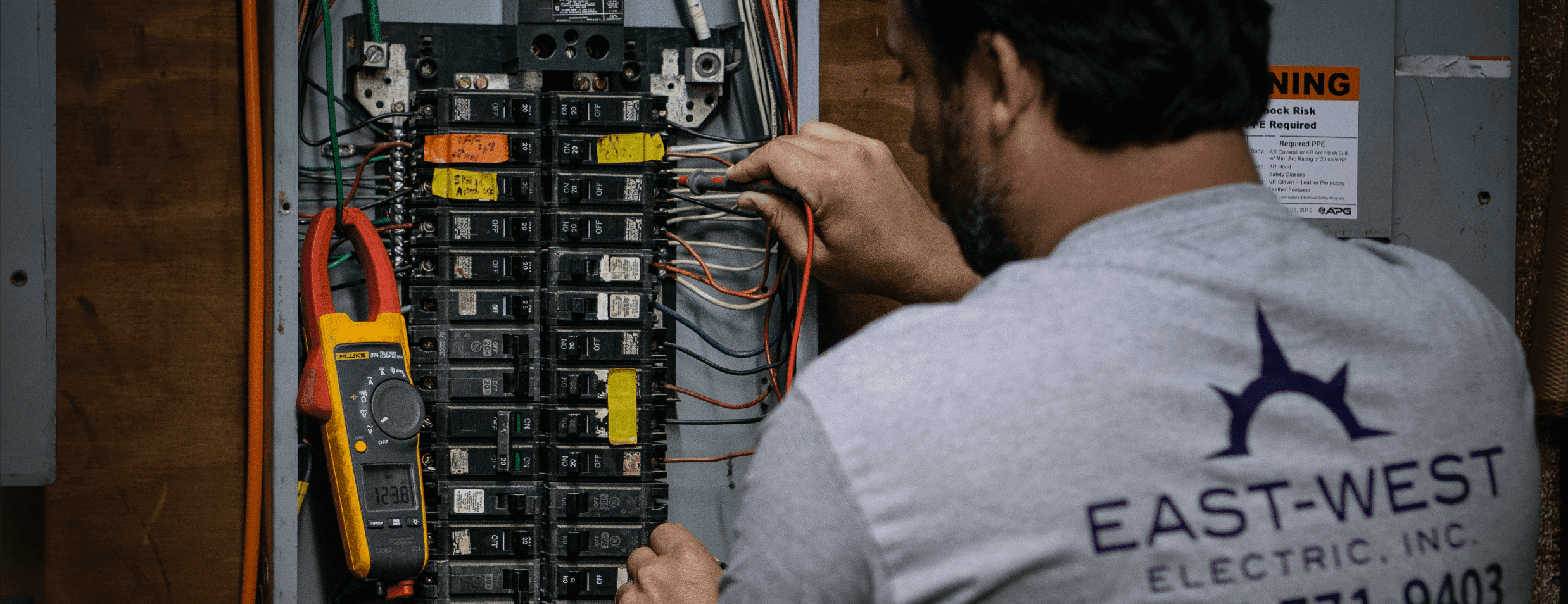

Here at East-West Electric, we employ the latest technology to analyze the vibrations and detect heat as a service to our customers. When there is excessive vibration the motor can get damaged by excessive heat.

It is critical to identify the source of these failures. Replacing the failed component only fixes the symptom and not the root cause.

#5 Poor Performance

You often are able to tell when an electric motor is working properly. You will see minimal vibrations and temperatures at a safe level. The operation at peak load has no issues.

Whenever your motor is near its end of useful life it’s quite the opposite. You will see plenty of problems. You may notice the motor can’t keep up with your facility’s demands. In this case, you need to control with an industrial electrician to talk about replacement or service options.

A New Electric Motor Can Save You Money

If your facility’s electric motor is more than a decade old it could be working on borrowed time. It’s only a matter of time before it wears and fails, leading you to downtime.

A new electric motor can offer:

- Factory warranty: warranties often go beyond 1-year repair warranty

- Less downtime: downtime can always mean lost profits and unhappy customers. A new motor can offer an immediate solution to downtime.

- Energy Efficiency: the older the equipment the less energy efficient it is. A new electric motor will save you money on the electricity bill every month.

Related Post: Save Energy in Commercial Buildings

Contact Us Today For an Inspection!

Feel free to run your electric motor issues by East-West Electric. We will find out if it’s time to replace or fix the problem. Contact us today at (727) 771-9403.